Products and Technologies

As a specialist manufacturer of automotive interior parts, we strive every day in our pursuit of lower costs, advanced functions, and productivity.

Technologies

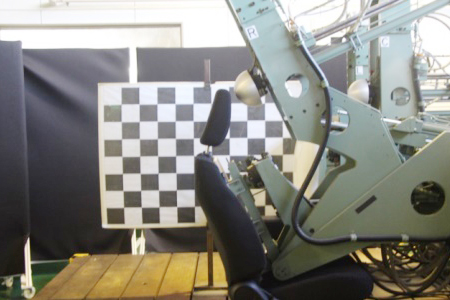

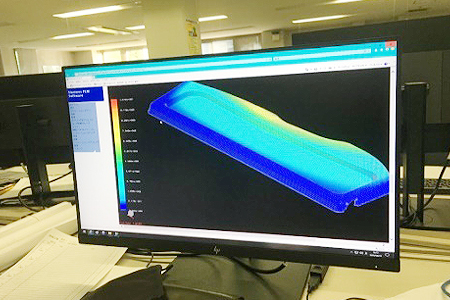

Acoustic analysisUsing sound data to propose materials with optimization analysis

In recent years, there has been a growing demand for quietness in vehicle cabins. To meet our customers’ needs in this regard, we use SEA analysis at all stages, from materials to finished products, to pursue optimization in the development of our products.

We also conduct analysis on current models, emphasizing deliberations that will lead to lighter weight and lower costs.

- Sound transmission loss measurement (anechoic chamber)

- Reverberant sound absorption coefficient measurement (reverberation chamber)

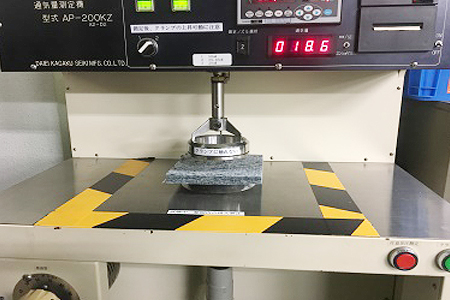

- Flow resistance measurement system

TestingRating and evaluation from an independent standpoint with an emphasis on results

Product Evaluation

At each stage, from prototyping to mass production, we perform confirmation testing that adheres strictly to standards, in line with the product requirement specifications.

Our testing equipment is inspected and calibrated in line with our proprietary standards to ensure that we report reliable evaluation data to the various relevant departments.

- Headrest static moment testing

- Seat mount/dismount durability testing

- 3D measurement device and 3D mannequin

- Large-scale thermo-hygrostat bath

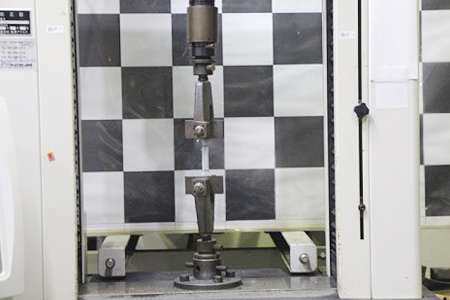

Material Evaluation

Right from the development stage, we conduct a range of evaluation tests on the textile and plastic materials used in carpets, roof linings, and other parts.

As well as the results of these evaluations, we also provide appropriate feedback to the engineering staff on all other aspects, including the testing conditions.

- Tensile stretch testing

- TABER abrasion test

- Flame resistance test

- Air permeability test

PrototypingProducts born from skills and knowledge

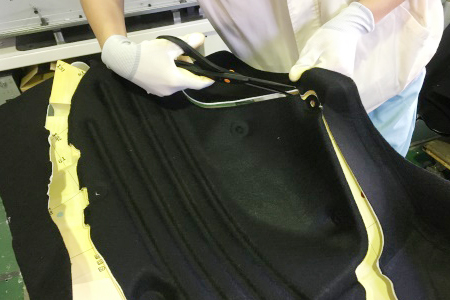

Seats:

Combining the skills that have been passed down and carried on since the company’s early days with state-of-the-art CAD and CAM, we strive to perfect our products from the prototype stage, while also pursuing ease of manufacture at the mass-production stage.

We also actively work on improvements raised on the factory floor, including confirmation and guidance.

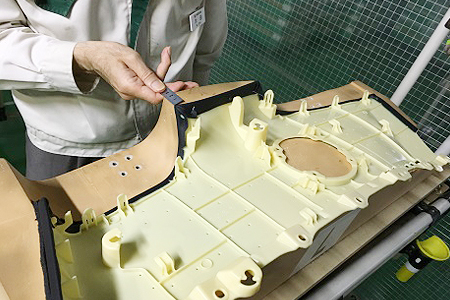

Interiors:

We perform prototype confirmation for the many and varied interior parts we produce, including carpets, ceiling, parcel shelves, fender liners, and door trims.

Because the majority of our production involves molding equipment, materials, shape, conditions, and other factors have a marked impact, so we coordinate closely on a daily basis with the design and testing staff in our product launch processes.

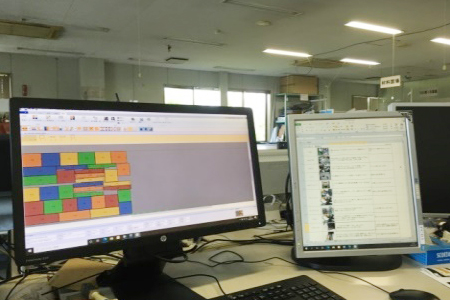

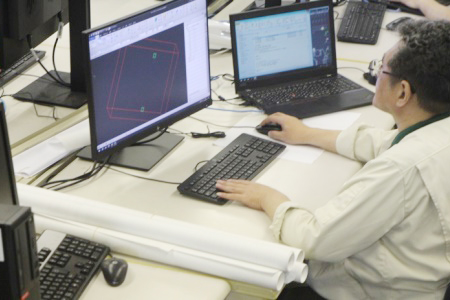

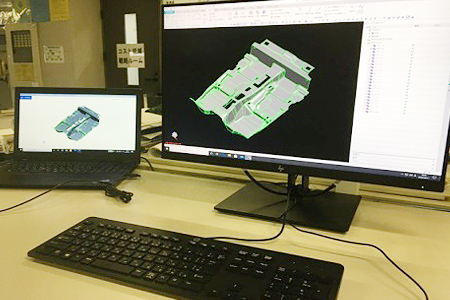

DesignDesigning Products for the Next Generation

In our design process, we take the customer’s specification drawings and offer proposals that take cost, quality, and productivity into consideration without sacrificing performance and function.

We make full use of 3D CAD and analysis system tools in the design of products.